Back

Product Parameter

| Item |

Parameters |

| Material Thickness0.7-1.2mm |

0.7-1.2mm |

| Driving Motor |

4kw |

| Hydraulic Station Power |

2.2kw |

| Type Changing Motor |

0.55KW |

| Curving Motor |

2KW Servo Motor |

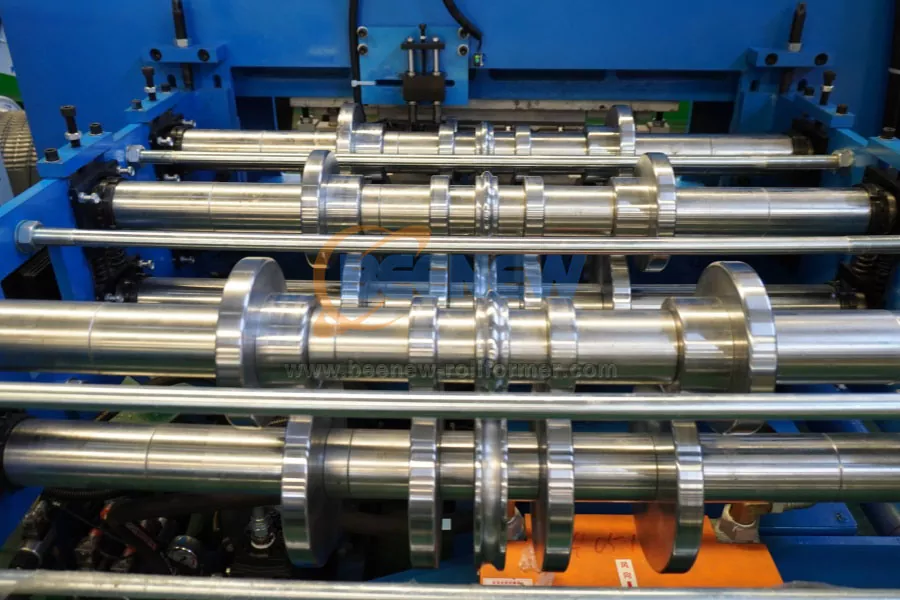

| Roller Material |

Cr12# steel, heat-treated, hard chrome coated

|

| Shaft Diameter |

65mm |

| Crimping speed |

15M/Min |

| Crimping Range |

250MM-600MM |

Features

Strong and durable

Machine base made from 80*80 square tube. Machine wall thickness is 28mm. All rollers of this standing seam curving machine are well treated. The intermediate hydraulic rollers are made from CR12#, finely processed after heat treatment, and the guide rollers made from 45# steel, fine-processed and hard chrome coated on the surface.

·Highly practical

The main material for standing seam roof panel machine is aluminum-magnesium-manganese plate. This machine can form 0.7-1.2mm thickness material, and for 1.0 thickness, minimum radius for positive bending can reach 1.5 meters, minimum radius for reverse bending is 6 meters. For 0.8-0.9 thickness plate, minimum radius is 2.5 meters for positive bending, for reverse bending is 6 meters.

Positive and reverse arcs can be bent continuously for 20 times with different radii on the same plate.

Fan-shaped bending uses the method of bending separately up and down, and fan-shaped bending can also be bent continuously on the same plate

Crimping effect:

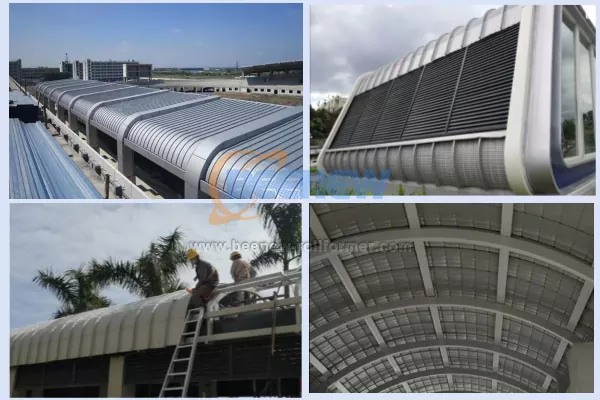

Project Cases

The standing seam crimping machine is widely used in construction industry, such as large exhibition halls, subway stations, stadiums, etc. The panels after crimping are practical and beautiful.