Back

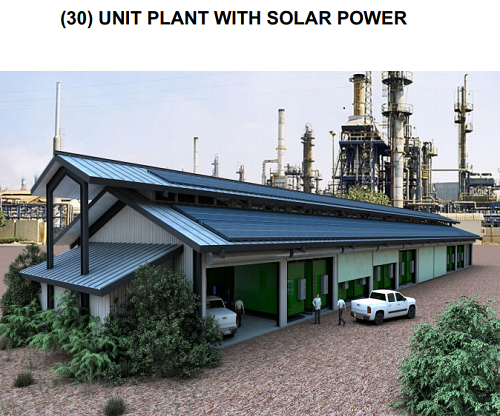

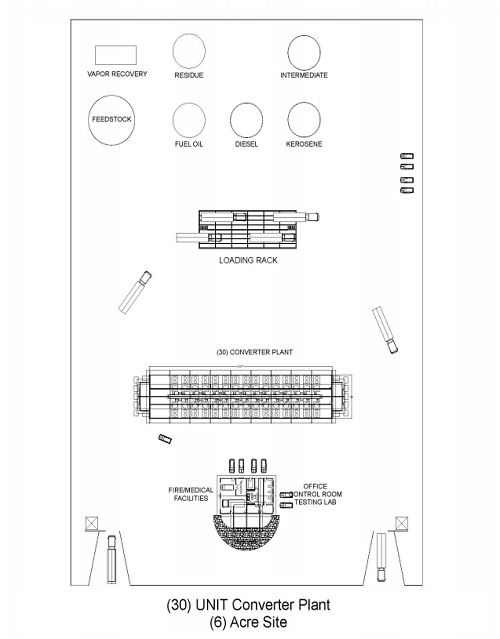

A Model for Eco Sensitive, Energy Efficient, Modular Refining, Containerized

.png)

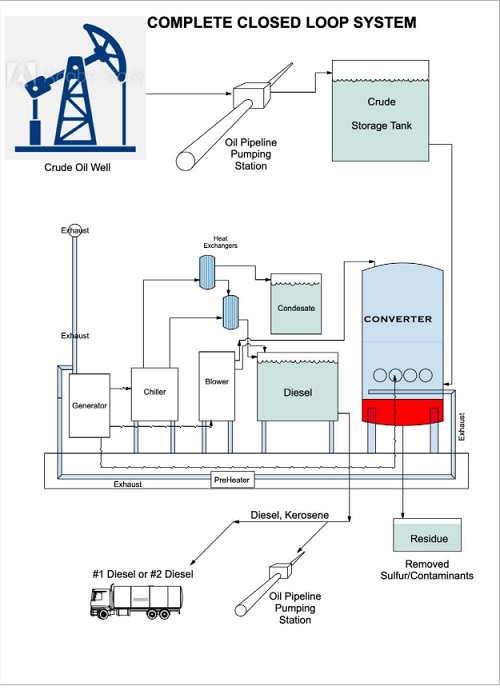

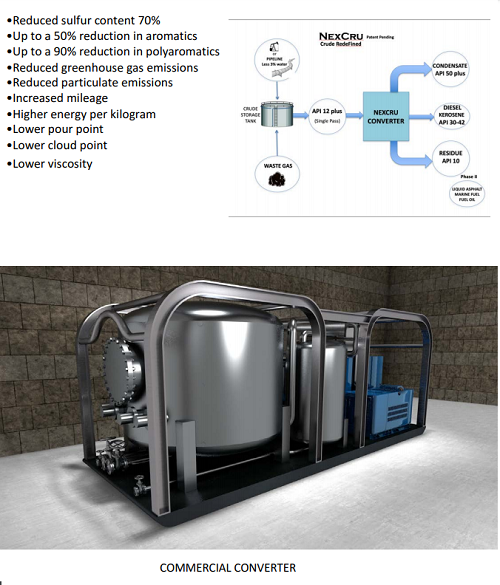

TECHNOLOGY DESCRIPTION & PATENTS NexCru converts crude oil utilizing natural well or waste gas at low pressure and a specialized range of targeted temperatures to affect an efficient, safe thermal process of crude oil, or distillate enhancement via sequential modular processing.

The conversion process allows to convert heavy & light API crude into useable off road diesel, kerosene and asphalt assets. Also segregates contaminates like sulfur to .005% and other metals yielding a more environmentally responsible and profitable fuel.

THE REVERSE DISTILLATION PROCESS: The refining of a hydrocarbon oil feedstock using reverse distillation by heating the feedstock to a temperature where two or more fractions will distill simultaneously in the presence of gas injection. The hydrocarbon vapors are then cooled under controlled conditions such that the separation of the components is condensed in an energy efficient process.

Crude Processing Technology

Under the Section