|

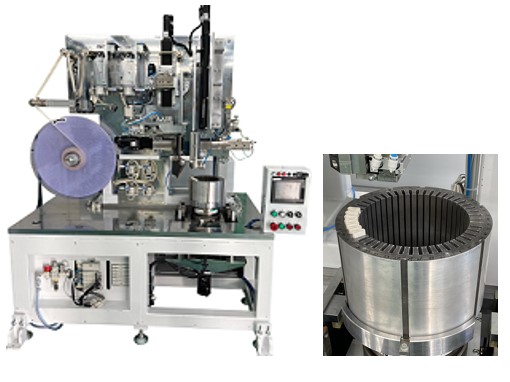

The machine folds, shapes and inserts insulation papers into the slots of a core from a paper roll. O-shape folding is usual. Cuffs version can be optional.

Insulation Paper Insert Machine

|

|

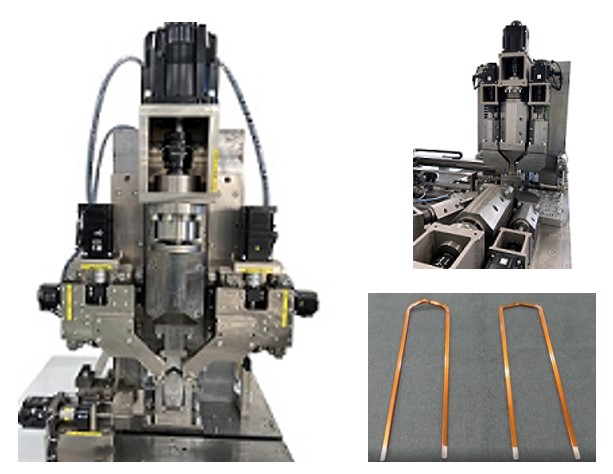

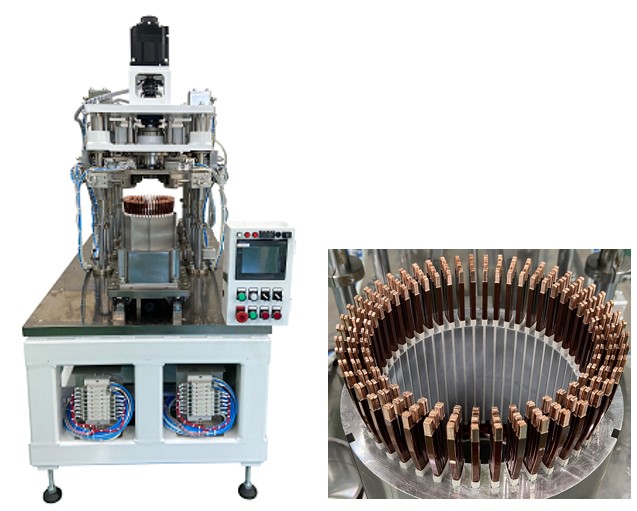

As one of forming methods, Bestec introduces combination of 2D and 3D forming separately. Another way is all forming on 1 machine. Either way can be connected to automation line.

Hairpin Forming Machine ```

|

|

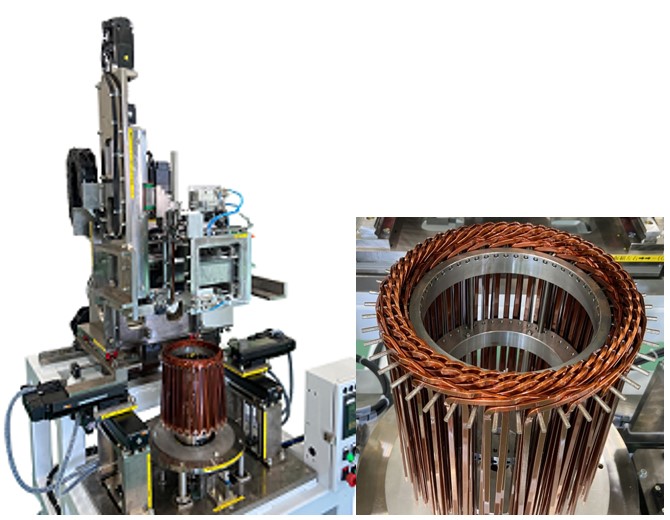

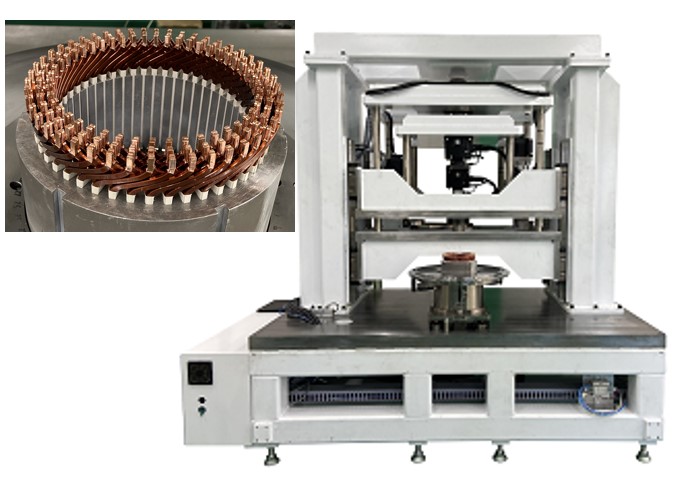

The machine inserts hairpin coils into basket by each layers. Different shape of coils are handled by changing cassette of coils by automatic or manual operation.

Hairpin Coil Assemble in Sub-basket Machine

|

` |

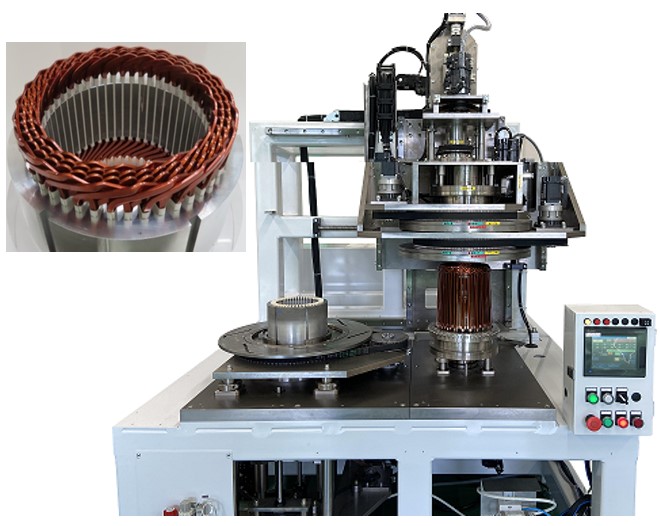

The achine picks up hair pin coils assembled in the basket, then inserts them into the core with caring insulation paper damage risk.

Hairpin Coil Insert into Core Machine

|

|

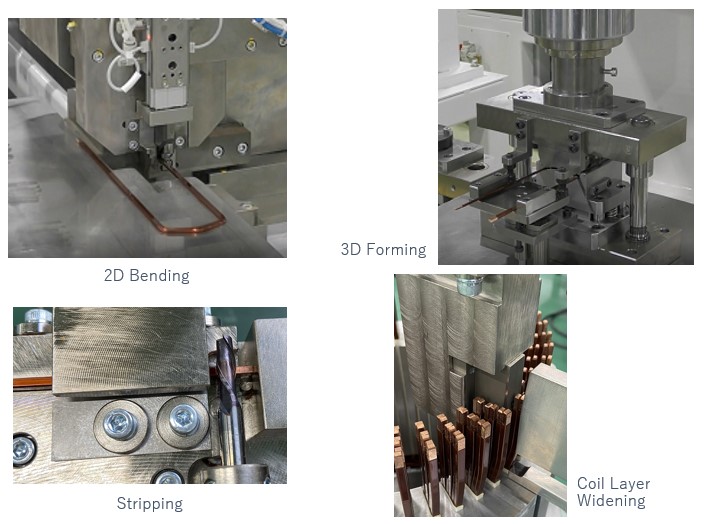

As a preparation of twisting at next process, widening layers is necessary. The machine applies a way of widening: using a circle jig to widen layers at multiple times.

Hairpin Coil Layers Widening Machine

|

|

The machine twists open side hair pin with each 2 layers. The height of coil legs is controlled at this process so trimming is not necessary for next welding process.

Hairpin Coil Twisting Machine

|

|

The machines are for sampling at trial stage with lower lead time and cost at hairpin forming, stripping, and coil layer widening.

Hairpin Coil Machines for Trial

|

| |