Back

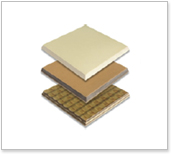

As Sole distributor in Korea of Norplex-Micarta who is the leading manufacturer of high performance thermoset composite materials, we have expanded our market to Power Generation, Oil / Gas and Heavy Industry.

Applications Market

ower Generation

The power generation industry is a large consumer of high temperature thermoset specialty molded shapes. Norplex-Micarta offers a full line of these composite materials, all certified to meet the most demanding industry specifications.

Oil & Gas

Norplex-Micarta products are suitable for pipeline gasket and pipe shoe support components of large-diameter piping transport systems. Thermoset composite materials are also used in piping for cryogenic insulation and support, and in cryogenic storage vessel and LNG carrier designs for thermal isolation.

Heavy Industry

Norplex-Micarta uses various resin and substrate combinations that allow thermal and mechanical performance to be tailored to specific heavy industry applications.

Medical Devices

Norplex-Micarta high performance materials are a good fit in many types of medical equipment. Parts made from cloth substrates are quieter and longer lasting than many metal parts and do not require lubricants, which may not be allowed in sterile environment

Electrical Devices

Norplex-Micarta produces high performance materials with various properties for use in electrical equipment such as motors, control devices, and power distribution units.

Transportation

The transportation industry is continually looking for ways to boost reliability while reducing component cost and weight. These objectives can be met by replacing metal or cast components with thermoset composite materials from Norplex-Micarta.

Applications

Power Generation Products

|

Grade

|

NEMA

|

Description

|

Applications

|

|

MC511A

|

G-11

|

MC511AF (NEMA G-11) is a high performance the thermoset epoxy fiberglass composite that provides higher strength than MC511AF

|

General, Blocking

|

|

MC511AF

|

G-11

|

MC511AF (NEMA G-11) is a high strength medium weight fibergalss epoxy resin composite that offers excellent physical, mechanical and electrical properties at both room temperature and elevated temperatures

|

General, Blocking

Wedges

|

|

MC500A

|

G-10

|

MC500A (NEMA G-10) is a glass fabric combined with a halogen-free epoxy resin system

|

Blocking

|

|

S511RS

|

Li-6

|

Molded Ripple Spring

|

Top Ripple Spring

|

|

MP310HT

|

C

|

MP310HT combines a cotton canvas fabric with general-purpose phenolic resin

|

Wedges

|

|

NP342LS

|

C

|

NP342LS consists of cotton sheeting combined with a general-purpose phenolic resin system

|

Wedges

|

|

NP500A

|

G-10

|

NP500A (NEMA G-10) is a glass fabric combined with a halogen-free epoxy resin system

|

General, Wedges

|

|

NP511

|

G-11

|

NP511 (NEMA G-11) combines a woven glass fabric and a high temperature epoxy resin system (Tg over 180℃) that is non-brominated

|

General

|

|

NP572

|

G-11

|

NP572 (NEMA G-11) is a high strength medium weight glass epoxy composite that offers excellent physical, mechanical and electrical properties at both room temperature and elevated temperatures

|

General

|

NEMA : National Electrical Manufacturers Assoclation

Product Matrix

| |

Polyester

|

Vinylester

|

Epoxy

|

Phenolic

|

Melamine

|

Vinylester

|

Silicone

|

Polyimide

|

|

Chopped Glass

|

BMC

/ SMC

|

BMC

/ SMC

|

BMC

/ SMC

|

Phenolic

Molding

Compound

|

|

|

|

Molding

RTM

|

|

Continuous Filament Glass

|

NEMA

GPO

IEC UPGM

|

|

IEC EPGM

|

|

|

|

|

Punching

Maching

Pultrusion

|

|

Glass Fabric

|

|

|

NEMA FR4

/G10/G11

IEC EPGC

|

NEMA G3

IEC PFGC

|

NEMA FR4

/G5/G9

IEC MPGC

|

NEMA G7

IEC SIGC

|

NEMA G30

|

Punching

Maching

|

|

Paper

|

|

|

|

NEMA X

Grade

IEC PFCP

|

|

|

|

Punching

Maching

|

|

Cotton

|

|

|

|

NEMA X

Grade

IEC PFCC

|

|

|

|

Punching

Maching

|

|

Linen

|

|

|

|

NEMA X

Grade

IEC PFCC

|

|

|

|

Punching

Maching

|

|

Exotics

|

|

|

Complex Laminates

|

|

|

|

Applications

Norplex-Micarta produces sheets, tubes, rods, and other specialty molded shapes for hundres of thousands of different applications in dozens of different industries.

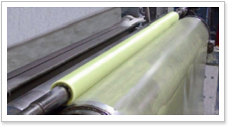

Utilizing custom designed equipment, in China, Norplex-Micarta can produce pre-preg up to 1520mm wide.

Maximum sheet width is 1440mm which may allow certain applications to achieve even greater part yield from a sheet.

Sheets are regularly produced from 0.127mm to 150mm in thickness, and even greater thickness are possible upon request.

Tubes, Rods, and specialty shapes are produced in the USA to customer specifications.

|

. |

| Norplex-Micarta also fabricates materials to customer requirements. Machining capabilities include CNC lathes, Mills, and Routers as well as sanding and other standard machining processes |

Norplex-Micarta’s production occurs with environmental protection in as a basic requirement. All manufacturing processes are controlled and include significant investment in thermal oxidizer. |