Back

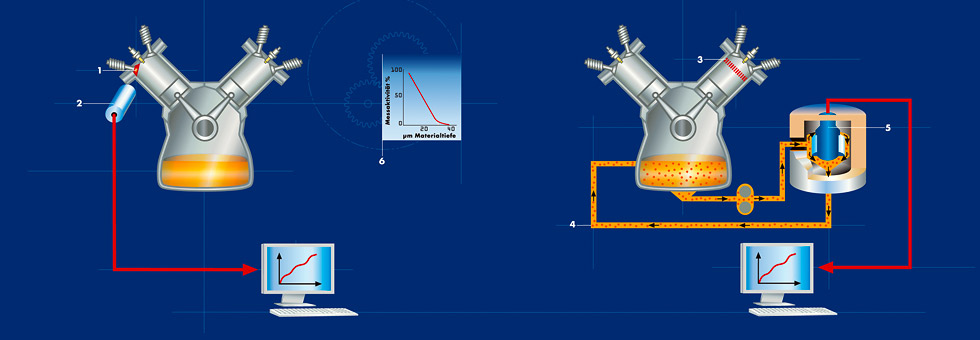

The Thin Layer Difference Method TLM

The decrease of the radioactive labelled layer (valve seat) is detected through the cooling jacket during regular operation by a gamma radiation detector at the outer housing wall.

The wear diagnostics instrument determines the wear values on the basis of the specified calibration ratio: measuring activity versus material depth.

Typical resolution value: 0.1 µm at measuring periods of several minutes and label activity of approx. 4 MBq. The measuring sensitivity can reach several nanometers.

The Concentration Measuring Method CMM

This method comprises a sensitive measurement of the concentration of radioactive wear particles in the lubricant with a gamma ray detector in the flow chamber of the measured activity concentration in the lubricant.

Resolution of the wear measurement by CMM depends on the oil volume in the machine and generally beats the TLM measurement by an order of magnitude. The required levels of radioactivity are considerably lower for the concentration measurement than for the TLM method. Precondition: The wear particles of the labelled component enter the lubricant circuit and diffuse homogeneously.TLM and CMM are included in one Software package. The detectors of the concentration measuring device CMD and the reference measuring device RMD can be applied for TLM measurements.