Back

Main unit of MPTH-Multi

Purpose: A furnace type of thermal CVD system for the formation of ZnO nanorods on substrates.

Features:

・Higher sealing performance, compared with commercial box type furnaces.

・Both of low-pressure and atmosphere-pressure operations are possible.

・Gas controllers will be customized based on the purpose or request of the customers

・Compact size, steady chassis

In developments of new materials, thermal treatment or surface treatment in an high-purity inert gas ambience, reactive gas ambience, or vacuum will be required. Usually box type furnaces are used. However, the seal in the box type furnace is not good because of their structure. In our system, tube furnace is adopted, and high sealing performance is achieved, so that high quality processes are available.

Detail specifications will be flexibly changed and customized based on the requests of the customers.

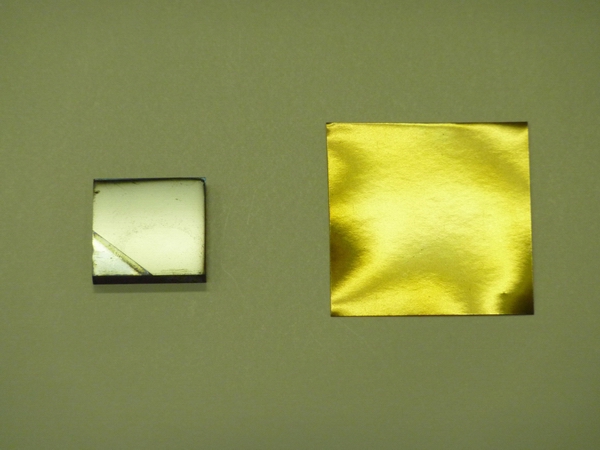

Nitrided Titanium showing golden color

Specifications

|

Configuration

|

Tubular Furnace

|

Operating Temp.

|

400~1000℃

|

|

Control of Temperature

|

1zone Program Control

|

|

Dimension

|

W300㎜×H200㎜×D186㎜

|

|

Electric Capacitance

|

500W

|

|

Furnace Tube

|

Material

|

Quartz

|

|

Dimension

|

OD30㎜×ID26㎜×L750㎜

|

|

Control of Gases

|

Gas Flowmeter

|

|

Introduced Gases

|

Carrier Gas:N2 or Ar

|

|

Vacuum Gauge

|

Bourdon Gauge

|

|

Vacuum Pump

|

Oil-sealed Rotary Vacuum Pump

|

|

Dimension

|

W156㎜×H200㎜×D300㎜

|