Back

Vertically-aligned CNT films cannot be directly grown on a polymer film or sheet, because any polymer has a melting point that is much lower than the CNT growth temperature. However, VACNT film grown on an inorganic substrate can be transferred to a polymer film by applying a thermal transfer method.

After the transfer process, the top end of each VACNT on the organic substrate is caught strongly by the polymer film due to a plastic strain, and the bottom end of each VACNT on the organic substrate is easily detached from the substrate. As a result, the vertically-aligned structure of the CNTs transferred on a polymer film is still maintained.

Thanks to the flexibility of a polymer, applications of VACNT to complicated objects or devices will be possible.

VACNT/Polymer

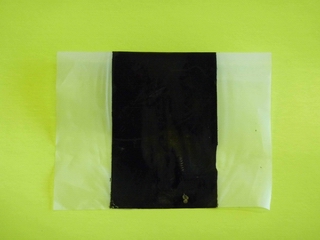

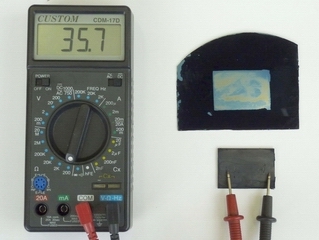

VACNT transferred to a polyethylene film. Because the surface of a VACNT film has a magic-tape-like structure at nanoscale, the film can be stuck on a smooth surface (such as a white board)

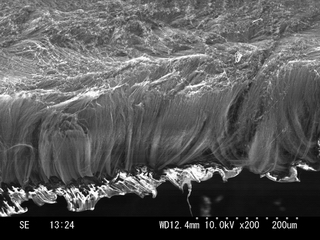

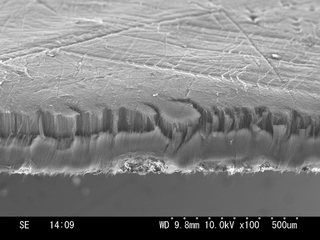

SEM image of VACNT on a polyethylene film showing that the vertically-aligned structure is maintained.

VACNT transferred on a Teflon sheet

VACNT/Rubber

CNT transferred on a rubbe VACNT grown on a Si substrate

VACNT/Paper

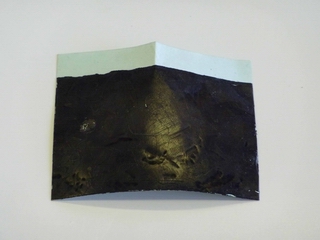

VACNT can also be transferred on a paper, which has a high handling ability.

VACNT transferred on a paper Cross-section SEM image of cut VACNT/paper