Back

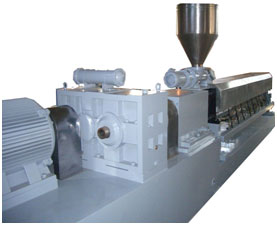

It is quite difficult to process PVC cable materials, so we usually have to use Two-Step Granulator Unit, which consists of one Parallel Co Current Twin-Screws Granulator and one Single Screw Granulator. Because it includes two machines, the stability is relatively poor, easier to happen mechanical failure, and the energy consumption is also higher. However, our product, Conical Co Current Twin-Screw PVC Cable Materials Granulator, recently successfully researched and applied for national patent product (patent application No.:2005101189153), can instead of Two-Step Granulator Unit to process PVC cable materials. This product successfully solves the problem of replacing Two-Step Granulator Unit with One Main Machine, recognized and affirmed by well known experts of Beijing Chemical Industry University. At present, the technology of Conical Co Current Twin-Screw PVC Cable Materials Granulator is leading the international level.

Comparison:

- The maximum output of 75/180 "Conical Co Current Twin- Screw PVC Cable materials Granulator" in the market today (motor power respectively: 132 KW and 55 KW) is about 700KG/H, and the motor power consumption is about 135 KW/H.

- The maximum yield of "SJSZ-75 Conical Co Current double screws PVC cable materials granulator" (Screw effective length: 4500 mm, motor power: 90 KW) can achieve 700 KG/H, and the hourly consumption of motor is only 75 KW, saving electricity more than 30%.

- Calculate on the base of working 12 hours per day:

- The output of 75/180 Two-Step PVC Cable Materials Granulator Unit is 8400 KG, mainframe power consumption is 1620 degrees;

- The output of SJSZ-75 Conical Co Current Twin-Screw PVC Cable Materials Granulator is 8400 KG, the consumption of the main power is 900 degrees.

Conclusion from the above data

Compare with Two-Step PVC Cable Materials Granulator Unit, Conical Co Current Twin-Screw PVC Cable Materials Granulator saves about 700 degrees in 12 hours, and about 1400 degrees in 24 hours. At the point of energy-saving, using one set Conical Co Current Twin-Screw PVC Cable Materials Granulator can save electricity fee300,000 (12 hours/day) or 600,000 (24 hours/day). Thus, you can earn the cost of one set Conical Co Current Twin-Screw PVC Cable Materials Granulator in one year.

- Brief introduction

On the base of the advantages of high extruding pressure and good plastic performance, Conical Co Current Twin-Screw PVC Cable Materials Granulator has reached the effects of higher mixing and higher plasticization. The result of identification showed: the output of this product is as twice as other granulators existing on the market, and the consumption of electricity saves more than 30%. Besides, it has the advantages of smaller noise and longer service life of screws. Therefore, it is the perfect machine for granulating PVC cable materials.

- Configuration

- All transducers use Japan Fuji

- Temperature controller of electrical control cabinet use Japan Fuji

- Bearings of distribution boxes all use Japan NSK, IKO

- All switches and contacts use ABB

- Motor use domestic famous brand "Pioneer"

- Barrel inside use alloy spraying

- Fragile place of the screw use alloy spraying

- Technical requirements

- Electricity demand:

- total power of the crew: 220 KW

- 380 V, 50 Hz

- Technical parameters:

- Diameter of screw φ75/φ150mm

- Running direction of screw the same

- Running speed of screw 5-78m/min

- Efficient length 4500mm

- The capacity above 700kg/h

- The main electric motor 90 KW/4 tiers

- External dimensions (L * W * H) 7683 × 1100 × 2500mm

- Attached spare parts and tools

- Screwdriver: 4

- 75 open end wrench: 1

- Special copper bar: 1

- Inside hexagonal wrench: 1

- Exhaust room "O" ring: 3

- Special instruments for removing the screw: 1 set

- Box wrench 27-30: 1

- Box wrench 36-41: 1

- Attached documents

- Product qualification certificate

- Circuit diagram

- Mainframe instruction

- Frequency converter instruction

- Temperature controller instruction

- Pressure cell instruction