Back

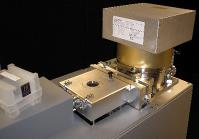

MPS-200L-RIE— Metal Etch System

Advanced systems for use with toxic or corrosive gases or when contamination must be eliminated from your process. Available with Plasma etch, RIE, PECVD, and with ICP sources.

Realize your process objectives from initial design right into production with the most reliable loadlock system you can buy!

Excellent for corrosive or hazardous chemistries

Safely reduces particulate contamination

Etch metal, poly, Si trench, refractory silicides, III-V features, GaAs backside vias, or Deposit ILD's

Will process any size or shape substrate up to 300mm

Eliminates water vapor and other contaminants

Exclusive MagCouple(tm) loading robot - simple reliable operation and self-aligning

Increase your throughput with quick pump downs.

Safe, rugged design means high reliability with remarkable uptime. Easy to use and simple to service

Product Summary

Whether your requirement is a sensitive etch process or a critical passivation deposition, the MPS-XXL Load Lock series gives you the safest, pristine environment to perform all your critical dry processes in. Our unique MagCouple transfer robot offers the most trouble-free shuttle system on the market today. You simply load and press run and your substrates are processed fully automatically - with reliability and uptime all the competition is envious of.

MPS-XXL Features

Modular Design for Ease of Maintenance

Single or Dual Chamber

Batch or Single Substrate

Small Foot Print

Stainless Steel or Aluminum Process Chambers

Cost Effective Process Solution

Automatic Process Controller using Windows®

MPS-XX0L available in 50-150, 200, & 300 mm versions

Single wafer or a variety of cassette load locks are available.

The MPS series is also available as an OEM module to integrate to existing system platforms.