Back

MPS-XX0PL — Cluster Tool

The versatile multi-chamber cluster tool for all of today's most demanding process. The MPS-X00-Locus allows you to tailor a cluster tool to your exacting requirements - without breaking the bank

Multiple chambers for different processes or chemistries

Configure for any RIE, ICP, or PECVD application

Etch metal, poly, Si trench, refractory silicides, III-V features, GaAs backside vias, or Deposit ILD's

Deposit SiO2, SiNx, Amorphous Si, Oxynitride and carbon films, passivation and ILD films for III-V and HTSC compounds

Multilayer processing without breaking vacuum

Excellent for corrosive or hazardous chemistries

Safely reduces particulate contamination

Eliminates water vapor and other contaminants

Safe, rugged design means high reliability with remarkable uptime. Easy to use and simple to service

Product Summary

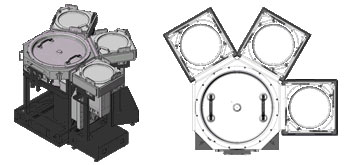

Our newest addition to the MPS family is a natural evolution to the line. Many of our customers had moved their MPS tools from R&D into production. They wanted a true production tool with greater throughput. Following our design ethic of integrating the best OEM components onto the MPS platform, we chose a 200 or 300mm transfer station as the center of the "locus". This allows you to choose up to 3 standard MPS process modules according to your process needs. Mix and match to double or triple capacity

MPS-Plasma Locus Features

MPS series is also available as an OEM module to integrate to existing system platforms.

- Modular Design for Ease of Maintenance

- 1 to 3 Process Chambers

- Batch or Single Substrate

- Small Foot Print

- Stainless Steel or Aluminum Process Chambers

- Cost Effective Process Solution

- Automatic Process Controller using Windows®

- MPS-XX0PL available in 50-150, 200, & 300 mm versions

- Single wafer or a variety of cassette load locks are available.

Under the Section