Back

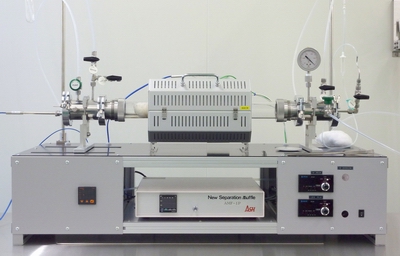

Thermal CVD system for CNT synthesis [MPCVD-50] ----- JPY4,800,000~

Main unit of MPCVD-50

Purpose: A furnace type of thermal CVD system with a catalyst-precursor providing function is designed for researchers to synthesize various forms of carbon nanotubes (vertically-aligned, long-length, and powdery CNTs).

Features:

・Ethanol liquid can be used as carbon source, as well as hydrocarbon gas; good effect

for SWCNT synthesis.

・Catalyst-precursor providing function is equipped;

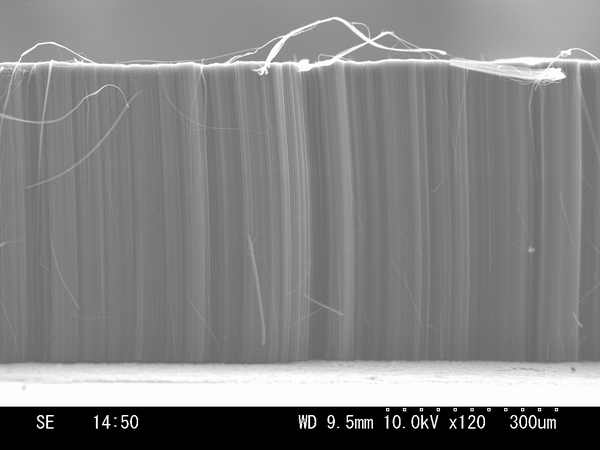

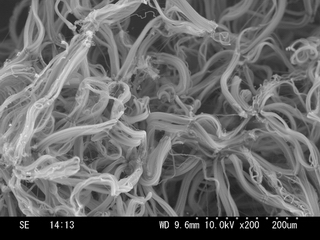

Long-length ( ~500 um) vertically-aligned CNT films and powdery CNT can be synthesized.

・3 lines of precise mass-flow gas controllers are equipped.

・Compact size, steady chassis.

This is a carbon nanotube CVD synthesis system which uses a horizontal quartz tube furnace (diameter = 50 mm). This system is suitable for stably producing vertically-aligned CNT on substrates and powder CNT in large quantity. This system produces almost the same type of CNT as the mini CVD system MPCNT-Premium, but it reproduces CNT products at more stable qualities and quantities. It is also capable of growing CNT on the outer surface and inside of samples with complicated three-dimensional shapes.

The system is equipped with a catalyst-precursor providing mechanism, by which the catalyst precursors can be introduced easily: just placing catalyst precursors on the special holder on the upstream side of the quartz tube, where the catalyst precursors are sublimed by the residual heat of the quartz tube and flowed by the injected gas.

The ethanol injection unit is equipped with a titration-based flow control system. The gas introduction unit is equipped with 3 lines of mass flow gas controllers (inert gas, hydrocarbon gas, and hydrogen gas). The process that Microphase recommends is capable of producing CNT with a combination of acetylene gas and a catalyst precursor.

The vacuum exhaust system enables this system to operate at a wide range of gas pressure from atmosphere to low pressure (10 Pa), and also to be usable as a thermal treatment system such as a vacuum furnace, atmosphere furnace, and nitriding furnace besides a system to produce CNT.

Figure of system components

Vertically-aligned CNT As-grown long-length powder CNT

Specifications

|

Configuration

|

Tubular Furnace

|

Operating Temp.

|

400~1000℃

|

|

Control of Temperature

|

1zone Program Control

|

|

Dimension

|

W300㎜×H200㎜×D186㎜

|

|

Electric Capacitance

|

700W

|

|

Furnace Tube

|

Material

|

Quartz

|

|

Dimension

|

OD50㎜×ID46㎜×L900㎜

|

|

Control of Gases

|

Mass Flow Controller

|

|

Introduced Gases

|

Carrier Gas:N2 or Ar

Reducing Gas:H2

Hydrocarbon Gas:C2H2 or C2H4 or CH4

|

|

Vacuum Gauge

|

Bourdon Gauge

|

|

Vacuum Pump

|

Oil-sealed Rotary Vacuum Pump

|

|

Dimension

|

W156㎜×H200㎜×D300㎜

|

|

Feed Mechanism for Liquid Fuel

|

|

Feed Mechanism for catalyst precursor

|

|

Dimension

|

W1100㎜×H1000㎜×D500㎜

|