Back

NEC manufactures a complete line of all metal and ceramic, bakeable beamline components for ion and electron beam systems. While many components are custom made below are some more common components.

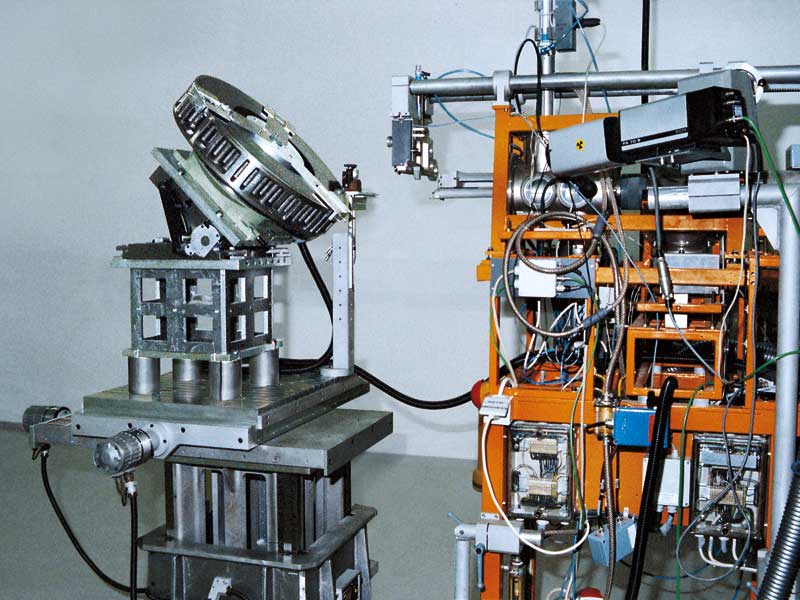

The unique design of the NEC beam profile monitors (BPM) has made them among the most popular and reliable beam diagnostic instruments available. NEC has provided over 2,000 BPMs worldwide. The NEC BPM reliably gives accurate information concerning the ion beam cross-section for ion beams with currents as low as 1nA for most models. Our newest model can monitor currents in the fA range.

Applications

The NEC BPM system is ideally suited for applications that require instantaneous scope display of beam cross-sectional shape and position without significantly interrupting beam transmissions. Particle beams of electrons, ions, or energetic neutrals are monitored.

Design

The unique patented design of the NEC BPM relies on the collection of secondary electrons from a grounded scanning wire. This arrangement eliminates contact noise at the rotating scanning wire.

A helical wire sweeps across the beam twice during each revolution to give a Y profile in a half revolution and an X profile during the next half revolution. A cylindrical collector around the grounded wire collects beam-induced secondary electrons from the wire to provide a signal proportional to the intercepted beam intensity at every instant. This signal is then sent to the NEC controller and to an oscilloscope for direct viewing of the beam profile.

There are four models of BPMs, with various versions of each model. Below is a brief description of each model.

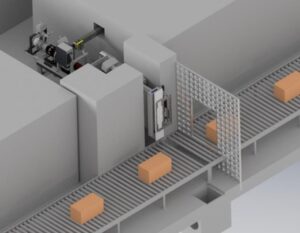

The NEC Faraday cups are designed for accurate measurement of ion beam intensity.

Applications

NEC manufactures various types of Faraday cups for a variety of applications involving the monitoring of ion beam currents. NEC offers 3 different models.

FC18: For applications involving high energy or high current

FC50: For applications requiring maximum beam clearance when the cup is retracted

FC28: For applications involving nanosecond pulsed beams

Design

The configuration of NEC Faraday cups varies from model to model dependent upon power rating and application requirements. However, all NEC Faraday cups are equipped with electron suppression assemblies and can be biased for accurate beam current readings. The suppressor is necessary to return secondary electrons, which affect the beam current readings. The cup is made of tantalum to limit neutron production.

All standard models utilize a molybdenum beam aperture that protects the insertion mechanism and assures proper operation of the suppression assembly.

The position of the Faraday cup is controlled by a pneumatic cylinder, which is actuated by air pressure. The motion is transmitted through a bellows seal to move the Faraday cup to one side of the beam path.

Below is a description of the three standard models. Custom cups based on any of these designs may be available upon request. Please contact NEC for further information.