Back

|

|

|

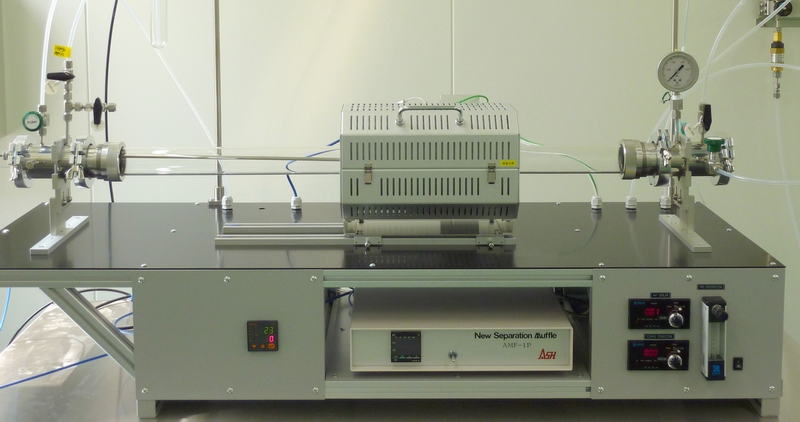

| Sample-heating (before sliding hot-zone of furnace) |

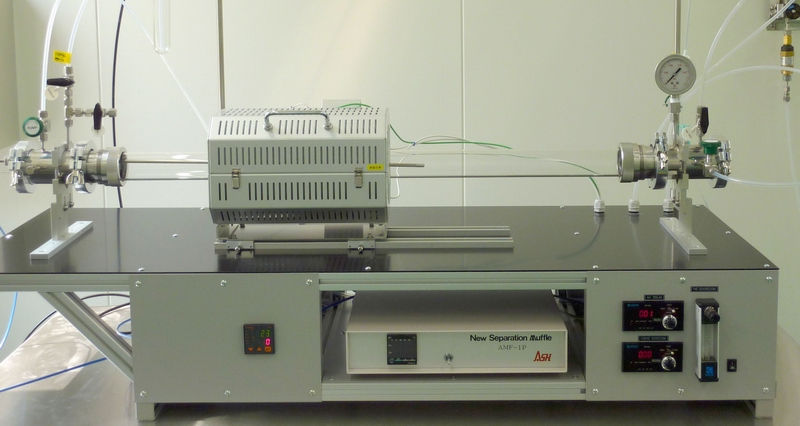

Sample-cooling (after sliding hot-zone of furnace) |

Purpose: A furnace type of thermal CVD system, equipped with a rapid heating/cooling mechanism, is designed for researchers go grow graphene films on substrates (Cu foils, etc.).

Features:

・Furnace-sliding mechanism is equipped for rapid heating/cooling of samples.

・A special thermocouple sensor is equipped for directly monitoring of the sample

temperature.

・3 lines of precise mass-flow gas controllers are equipped.

・Compact size, steady chassis.

・Other carbon nanomaterials (carbon nanotubes, carbon microcoils) can also be

synthesized.

This is a special thermal CVD system for synthesizing graphene films with a horizontal quartz tube furnace (diameter = 50mmφ). A catalyst substrate (usually Cu foil) is placed inside the furnace, and methane gas or acetylene gas is injected from the outside at a low flow rate and low pressure to form a graphene film on the catalyst foils.

It has been known that the cooling speed is a key factor for forming high-quality graphene films. Rapid cooling suppresses the excess deposition of carbon from the catalytic metal foils (such as Cu or Ni foils).

This system is equipped with a rapid cooling mechanism. The tube furnace slides 30 cm sideways to the reaction tube, and the hot zone of the furnace can be moved away from the sample. Shifting the hot zone rapidly cools the sample. This system realizes an extremely rapid cooling effect with a simple mechanism.

Graphene CVD System