Back

NEC manufactures both positive and negative ion sources for a variety of applications that range from a few microamps to over one hundred microamps.

DesignApplications

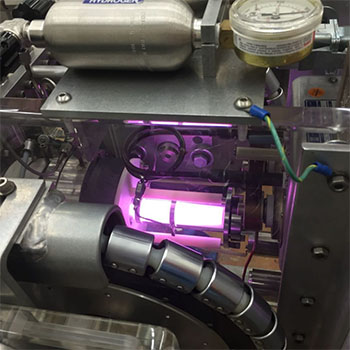

The SNICS II is the most versatile negative ion source presently available. This sputter cathode source produces ion beams for all elements that form a stable negative ion. Its unique design and metal/ceramic construction with no organic seals in the main housing of the source has produced a reliable system with superior performance for all negative ions across the periodic table.

diagram of SNICS internal components

Cesium vapor flows from the cesium oven into an enclosed area between the cooled cathode and the heated ionizing surface. Some of the cesium condenses on the front of the cathode and some of the cesium is ionized by the hot surface. The ionized cesium accelerates toward the cathode and is focused on the front face of the cathode. The ionized cesium sputters particles from the cathode through a condensed cesium layer on the cathode face. In this way, negative ions are accelerated from the cathode surface.

The source is designed to allow the change of a cathode with minimal downtime. In Pelletron systems, it is common to change a cathode within 10 minutes from beam on target to beam on target.

Performance

Customers report emittances of the resulting negative ion beam from a SNICS II source from 3-5 πmm mR (MeV)1/2 for 80% of the beam, depending upon the beam mass.

Options

Though the source is primarily designed for the use of solid samples, NEC offers a gas cathode assembly, which allows the insertion of gas through the center of a cathode.

NEC also offers a similar source that can handle multiple cathodes – 40 or 134 cathodes. For more information on this source, please see our MC-SNICS source page.

Applications

The Multi-Cathode SNICS (MC-SNICS) source was originally developed as a reliable sputter source for applications that required rapid cathode change and precise, repeatable positioning without cathode exposure to air. This has proven to be especially beneficial in the field of Accelerator Mass Spectrometry (AMS), where it is used for the production of beams such as Be, I, Cu, Cl, and the actinides.

Design

There are two standard sizes of the MC-SNICS available – one that can accommodate 40 samples at a time, and one that can accommodate 134 samples.

Diagram of operation of the SNICS sourceCesium vapor flows from the cesium oven into an enclosed area between the cooled cathode and the heated spherical ionizing surface. Some of the cesium condenses on the front of the cathode and some of the cesium is ionized by the hot surface. The ionized cesium accelerates toward the cathode and is focused on the front face of the cathode. The ionized cesium sputters particles from the cathode through a condensed cesium layer on the cathode face. In this way, negative ions are accelerated from the cathode surface.

This is a very similar principle of operation to the single cathode SNICS source, with the exception of using a spherical ionizer instead of a conically shaped ionizer and the addition of an immersion lens and 40 or 134 position cathode disk.

The simple cathode indexing system has proven to be highly reliable. It is capable of reproducing the cathode position to within 0.002″ of its original position.

Performance

The beam emittance is on the order of 5 πmm mR (MeV)1/2 for optimum transmission through a tandem electrostatic accelerator with proper optics.